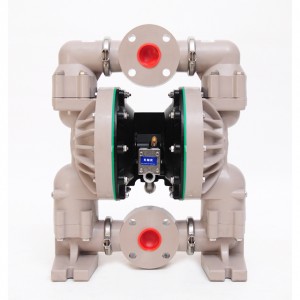

In a variety of applications across a number of industries, Air-Operated Double Diaphragm (AODD) pumps provide reliable, high performance pumping. They have come to be known as the ‘work horse’ of industry, when it comes to handling and transferring fluids at relatively low flows and pressures. Above ground or below ground; on land or on sea; in normal or extreme conditions; the versatility of AODD pumps ensures that processes keep moving.

For more information ask for sample report @ https://www.persistencemarketresearch.com/samples/27589

Additional costs may arise if pulsation dampeners are required to accommodate vibrations and surges in the piping systems. AODD pumps are very reliable since they have very few moving parts and components that can wear. They are easily dismantled for maintenance or diaphragm replacement. The main working parts are the valves, valve seats and diaphragms. Spares are generally fairly low cost, but it is vital to select the correct corresponding parts. For example, Neoprene is outstanding for general purpose as a low cost diaphragm that delivers the highest flex life. Teflon-based diaphragms are generally the most expensive, with other materials lying in between, so while the diaphragm used must be compatible with the fluid to be pumped, care should be taken to make sure that it is not over-specified, leading to unnecessary costs.

The report also offers a detailed assessment of the competitive landscape and identifies key players contributing toward the growth of the metering pumps market. The companies have been profiled in the report based on key parameters such as business and financial overview, recent developments, product portfolio, and geographical reach. A SWOT analysis has also been included to give readers a clear understanding of the players’ strengths, weaknesses, opportunities, and threats.

To Obtain All-Inclusive Information On Forecast Analysis Of Global Market, Request A Pdf Brochure Here.

Over the last five years, pump manufacturer Wanner International has achieved an average annual organic growth rate of more than 14%.

XploreMR recently published research study on the AODD (Air-Operated Double Diaphragm) Pumps market titled “AODD Pumps Market: Global Industry Analysis 2013-2017 and Forecast 2018-2028” offers a detailed value-volume analysis of the AODD Pumps market along with insights via BPS analysis (US$ Mn), attractiveness analysis and Y-o-Y growth on the basis of diaphragm material of construction, flow rate, application and end use industry. The volume analysis, for AODD Pumps market, has been done in units (i.e. the number of AODD Pumps) covering data for the historical period ranging from 2013-2017 and forecasted up to 2028 with 2018 as the base year.

We want to hear from you. We’re here to support the creation and sharing of information: if there’s something we aren’t doing, or something we could do better, let us know. We grow through your comments and ideas.

Besides enhancing safety, Cheek says a sealed system can prevent loss of expensive chemicals like acetone. “I haven’t lost any product due to the pumps. They eliminate evaporation, do not leak or drip and I can adjust the flow to get the exact amount I need without spilling or overflow.” Cheek says he also utilizes a GoatThroat pump to transfer comprehensive boiler water treatment solution to mitigate scale and corrosion of the boiler system. Previously, he had to fill a glass beaker with the chemical, climb a ladder and pour the chemicals into the top of the tank. Now, that work is performed with the help of the pump and 6’ extension hose accessory to efficiently deliver the cleaning chemicals. “Every time inspectors come in, they say we have the cleanest boiler they have seen,” says Cheek. “With this chemical transfer system, I’m able to transfer exactly what I need to get the job done.”

Compared to the previous centrifugal pump, the diaphragm plunger pump has been shown to be by far a better choice. The unit has proved to be trouble-free, is very quiet and impresses with very high efficiency. “The pump has been operating for more than 700 days without any fault,” says Puralube Operations Manager Michael Schlüter. The economy and availability predicted by the manufacturer have fully met expectations, as Schlüter confirms: “The investment for the new pump was completely returned within 14 months.” He was also impressed by the modern drive technology. “The level in the hot separator for the NOVADOS is set via a speed control by means of a frequency converter – this works very well and with a high level of control,” says Schlüter.

The latest advancements in Diaphragm Pumps industry and changing market dynamics are key driving factors to depict tremendous growth. Also, the risk factors which will have a significant impact on Global Diaphragm Pumps industry in coming years are listed in this report. The revenue-generating Diaphragm Pumps types, applications and key regions are evaluated. Top growing regions and Diaphragm Pumps industry presence cover Asia-Pacific, North America, Europe, Middle East, African countries and South America. This study also analyzes the top countries in these regions with their market potential.

According to Fact.MR’s study on the chemical injection pumps market, acquisitions will remain a vital strategy for competitors in a bid to improve market penetration and enhance global presence. Companies are expected particularly focusing on opportunities residing in the chemical and petrochemical industries across key regions. Strategic collaborations, acquisitions of associated businesses, and new product developments are cited to be the primary strategies implemented by chemical injection pumps providers in a bid to capture major shares in the global market revenues. Companies are emphasizing engineering of compact pump designs to eventually reduce the carbon footprint, which is fueling innovations in the chemical injection pumps market. While frontrunners in the chemical injection pumps market primarily adhere to mergers and product diversification, first-movers continue to rely on innovation strategies for market recognition.

NCBI ROFL: How is a giant sperm ejaculated? | Ptfe Lined Double Diaphragm Pump Related Video:

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for Duplex Diaphragm Pump For Petrochemical , Teflon Diaphragm Air Operated Pump , Air Operated Diaphragm Pumps , We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!