To analyse competitive developments such as expansions, agreements, new product launches, and acquisitions in the market.

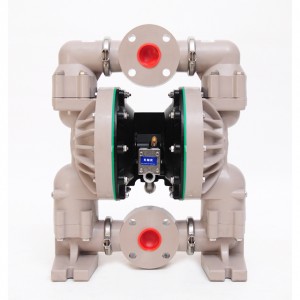

Diaphragm: The flexing of this elastomeric component is responsible for the pumping action. The material of construction for this critical component should be selected on the basis of its resistance to the aggressive fluid that is being handled. Options include neoprene, polyurethane, PTFE, Buna-N, EPDM, fluoropolymers, and chlorosulfonated PE.

This article identifies and recommends popular ball, seat and diaphragm materials (internal pump components) and pump fluid sections (pump bodies) to perform in applications with varying fluid characteristics.The key to the safe and reliable operation of an AODD pump is correct configuration. This involves taking fluid characteristics into consideration, for example, pH levels, abrasiveness, temperature and fluid density. The chemical compatibility is also important; manufacturers often provide guides to ensure pump materials are suitable for the fluid being transferred. These same websites often feature online pump selector tools to assist in configuring a pump in a matter of minutes and with a few clicks of the mouse.

During the BlueTech Forum conference, LG Sonic received the “Best Technology Innovation” award for the LG Sonic MPC-Buoy, a system that helps control algal blooms in surface water using real-time monitoring and ultrasound technology. More information on the system and how it can be used in industrial applications can be viewed in the March/April issue of Water Technology.

A California craft brewery uses peristaltic pumps to for purification of wastewater. The brewery and the packaging hall generate about 100,000 gallons of wastewater per day. A pump was needed that would not vapor lock from the aggressive off gassing from chemicals being injected. The brewery uses two peristaltic pumps to inject 12.5 percent sodium hypochlorite into the membrane bioreactor filter backwashes. A third pump injects 93 percent sulfuric acid prior to reverse osmosis, and an additional pump injects 12 to 14 percent sodium hydroxide to bring reclaimed water to a pH of 8 to prevent pipe corrosion. The peristaltic pumps allow the gas accumulation to be pumped through the tubing while maintaining a constant flow rate without vapor lock.

Industrial Growth Analysis of Electric Diaphragm Pump Market 2019-2025: The latest report on Electric Diaphragm Pump Market demonstrates that the global Electric Diaphragm Pump market will witness a steady CAGR over the next few years. The research report is a thorough analysis of market drivers, restraints, threats, and opportunities – giving a complete SWOT analysis. The report addresses the niche investment options for the players throughout the forecast period. The report details market estimates at a global and a regional level with respect to the existing and new players.

Also, augmenting demand for high-throughput screening and superior medical diagnostics has fuelled the demand for liquid handling technologies. The need for automated liquid handling technologies in cellular workflows and single cell analysis will further fuel the growth of liquid handling technologies market. Further, increasing spending on R&D in the field of health sciences and pharmaceuticals is expected to surge the demand for latest and state-of-the-art liquid handling technologies.

With approximately $12 million of revenue generated in 2018, All-Flo is expected to be accretive to margins of Dover and its Fluids segment. The acquisition is expected to generate double-digit cash Return on Invested Capital (ROIC) by Year 3.

Construction industry, especially in Asia Pacific region is expected to witness steady growth during the assessment period. This is thus expected to in turn drive the growth of diaphragm pumps market in Asia Pacific region. Increasing awareness about clean drinking water and increasing construction spending is expected to drive growth of diaphragm pumps market during forecast period. Anticipated steady growth in demand for oil and natural gas is expected to result in steady growth the market across developing regions of the globe.

Enquire Here Get customization & check discount for report @: https://www.marketresearchstore.com/report/global-hot-runner-systems-market-research-report-2018-513756#InquiryForBuying

The wide choice of liner materials available, and the ease with which liners can be changed, makes it economically feasible to use a single flexible-liner pump for numerous applications.

Read Detailed Index of full Research Study at:: https://www.marketresearchstore.com/report/global-civil-explosives-market-research-report-2018-2024-513735

This Canadian Hero Deserves Eternal Glory For Saving So Many Classic Saabs | Aodd Pump For Fluid Transfer Related Video:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Duplex Diaphragm Pump , Sulfuric Acid Diaphragm Pump , Chemical Pneumatic Double Diaphragm Pump , Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!